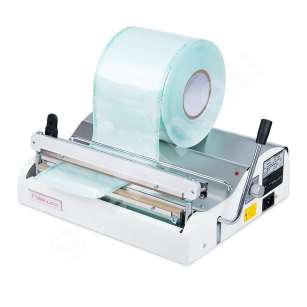

Sterilization sleeve sealer

Users expect sterilization sleeve sealers above all to be easy to use, reliable, and economical. In the day-to-day operation of a medical or dental practice, in larger healthcare centers, or within procedures governing central sterilization departments, operational continuity is crucial. It directly affects the speed and efficiency of medical material reprocessing. As is well known, the greater the availability of essential tools, instruments, and accessories, the more efficient the entire facility becomes, the more effective patient care is, and the greater the comfort for staff. Undoubtedly, every element of the broadly understood management process of a practice, healthcare center, or hospital—and every part of the infrastructure (including sleeve sealers)—impacts both clinical outcomes and economic results. The devices for thermal sealing of sterilization sleeves offered by sterim.eu meet all requirements for professional medical equipment, making them a valuable component of any facility’s equipment.

Rotary sealers and sealers with printers

Thermal sealing of packages is particularly effective wherever large quantities of reusable medical instruments are processed. This does not necessarily apply only to local or central sterilization departments serving large medical facilities. Even in a medium-sized dental practice with two or three dental units and several patients treated simultaneously, the number of sterilized instrument sets required for daily work can be significant. For this reason, sterilization sleeves are increasingly used in medical facilities of various sizes. In response to these needs, manufacturers offer sealers of different sizes and capacities—from compact devices designed for small practices to advanced equipment intended for intensive, round-the-clock operation in professional sterilization departments. Sealers offered by Sterim can be used to close packages in paper–film sleeves as well as Tyvek packaging. Precise adjustment of operating temperature allows optimal sealing conditions to be selected. Some devices are equipped with printers that facilitate the preparation of reports attached to sterilization process documentation.

What to consider when choosing a sterilization sleeve sealer

When choosing a sealer for a salon or practice, you should consider whether a simple sleeve sealer will meet your needs or whether a rotary sealer is required. A jaw sealer is sufficient for most beauty salons, podiatry practices, and small dental offices. A rotary sealer is more suitable for larger dental clinics or medical practices. Rotary sealers with displays are also available on the market, allowing adjustment of temperature and other parameters. Attention should also be paid to the device’s power, size, and available mounting options. Rapid heating of the sterilization sleeve sealer ensures a strong and reliable seal of the sleeve or other sterilization packaging. High sealing quality and tightness are key conditions for proper sterilization of the package. A sterilized sleeve stored after sterilization must remain sealed throughout its storage period, which is why the quality and power of the device are so important.

Seal integrity tests – sealing quality matters

Regular control of seal quality helps prevent potential errors, poorly sealed sterilization packages, and incorrect seals on sterilization sleeves. Universal seal integrity tests allow verification of devices from various manufacturers. Seal tests are easy to use and provide quick, clear results. Sterim seal tests enable convenient archiving, and their graphic design allows recording the most important information about the performed test. Proper sealer performance tests should be carried out periodically, depending on the equipment used, its quantity, and the number of sterilization packages prepared daily. The industry in which the sealer is used is also important, as regulations may differ between sectors.

Your order will be processed

Your order will be processed